WHY DID MY FOUNDATION CONCRETE CRACK?

Cracks in concrete are not indicative of inferior materials or workmanship. Cracking in concrete is the result of shrinkage that occurs as concrete hardens and cures. Cracks can be minimized and controlled, but not eliminated. Control joints are placed in concrete floors and exterior flatwork to encourage shrinkage cracks at controlled intervals, but this standard industry practice does not guarantee that cracks will not appear outside control joints.

Cracks in poured concrete foundations are not uncommon and are usually 1/8 inch or less in width and can run the full vertical length of a wall. These types of foundation cracks are not considered problems, until they leak. The presence of a hairline crack does not indicate any structural damage and there is no need for panic!

Lambert Concrete warranties all foundations for one year from the date the foundation was poured and will perform urethane injection of any shrinkage cracks showing leakage.

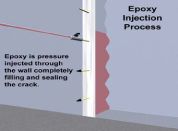

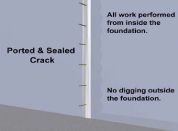

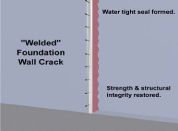

Foundation Crack Injection Process

Foundation cracks are sealed utilizing an injection process that seals the crack from the inside- out and eliminates water penetration. The pressure injection process pushes a urethane or epoxy resin through the wall, completely filling the crack as the cavity is injected from the bottom up.

Winter

Damage

For ANY exterior concrete flatwork installed within the past year, proper maintenance and care of driveways, sidewalks, porches, patios, and even garage floors during the first cold weather season is critical to minimizing damage to concrete flatwork surfaces. Freeze/thaw cycles during cold months are the most common cause of damage to the surface of concrete flatwork. Concrete is a porous material that will absorb moisture at the surface. When the absorbed moisture in concrete freezes, it exerts tremendous expansive force, which weakens the concrete and sometimes leads to the surface of the concrete scaling off.

Concrete less than one year old (and especially concrete poured after November 1st) is particularly vulnerable to freeze/thaw cycle damage in the first cold weather season. Lambert Concrete uses a concrete mix with a special integral sealer to help protect concrete during the first winter. In addition, a topical cure-and-seal product is also applied to the concrete the day of the pour. However, construction traffic, power-washing of new concrete surfaces, and environmental factors (sun, wind, rain, snow) can deplete these protections.

Protect Your Concrete

The following is a list of steps that can and should be taken to protect and prolong the life of your driveways, sidewalks, and other exterior concrete flatwork.

Warm Weather Care

CLEAN AND SEAL YOUR CONCRETE.

If you want your concrete to stay fresh and looking like new, you need to clean and maintain it!

Cleaning options for concrete include:

- Pressure Washing (Not exceeding 2,500 psi)

- Scrub Brushes can be used with a degreaser and hot water

- Trisodium Phosphate (TSP) - This product acts as a degreaser and can be found at home improvement stores.

Sealing your exterior flatwork every few years will help prevent a number of problems that concrete is prone to. By regularly sealing your exterior areas, you will extend the life of your concrete!

Benefits of sealing concrete include:

- Helps protect surfaces from the effects of the freeze/thaw cycles

- Increases durability

- Protects against discoloration, stains, mold, and UV rays

For more information on the different types of sealers available and tips on how to clean your concrete, click the links to visit Ozinga or Smith Ready Mix's websites.

Cold Weather Care

AVOID USING DEICING PRODUCTS IN THE FIRST COLD WEATHER SEASON.

Using deicing products increases the frequency of freeze/thaw cycles and exacerbates the weakening effects of freezing moisture on concrete surfaces. Deicers containing only calcium chloride are recommended after the first winter season.

NEVER USE ANY DEICING PRODUCT CONTAINING AMMONIUM NITRATE, AMMONIUM SULFATE, OR MAGNESIUM CHLORIDE.

These deicing agents chemically attack concrete and cause damage above and beyond the effects of freeze/thaw cycles. Some chemicals found in deicing products can also eat through any sealer that has been applied.

DO NOT PARK VEHICLES ON DRIVEWAYS.

Snow and water contaminated with road salt and deicers will drip from vehicles leaving concentrated areas of salt or deicer brine that will facilitate multiple freeze/thaw cycles at the surface of the concrete. Even though you may not be applying any deicing methods directly, your vehicles will pick up salt and chemicals from the municipal streets while driving around.